Oleh Dr. Devi Oktaviana Latif, S.T., M.Sc. dan Ir. Hotma Prawoto P S., M.T.

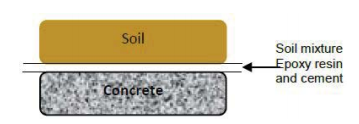

The foundation is an underground construction that functions to deliver loads to the ground. The foundation is used in unfavorable soil conditions where hard soils are found to be very deep. In Supporting the load above it, the pile foundation behavior relies on end bearing, friction resistance and combined end bearing and friction resistance. There are several factors that influence the behavior of the pile in supporting the load, namely the type of soil and the method of mounting the pile (put or drilled). At the piles that are located on cohesive soil and the bearing capacity is less profitable, the pile behavior relies on pile friction resistance. As for the pile mounting method in cohesive soils, it will usually result in a rise in ground level around the pile, followed by soil consolidation. To minimize the increase in surrounding soil, the drill is made first, and the precast pile is inserted into the drill hole without being fixed. In the implementation of the drilling method, the diameter of the hole is made larger than the diameter of the pile, so there is no bond between the pile and the surrounding soil. To fill the empty part of the drill hole, additional material is needed which is binding to the surrounding soil. This additional material is expected to be able to produce a pile resistance friction force against vertical loads. Additives used as ingredients added to this study are epoxy and cement resins which aim to increase friction resistance. This study examines the increase in friction resistance values on the soil and pile interfaces using direct shear. The test results show that the highest friction resistance values occur in the mixture with the proportion of soil: epoxy: cement is 62.5%: 25%: 12.5% with addition of 220 ml of water which is 1.1 kg / cm2 at 7 days curing time.

Untuk informasi lengkap materi dapat dilihat pada link berikut ini.

The Effect of Epoxy Resin and Cement …………..

Artikel yang sama telah terbit dan dapat diakses di Journal of Applied Engineering Science link ini.

http://www.engineeringscience.rs/article/Volume_17_article_591